BellVR platform at the SIGMA service center

Other apps

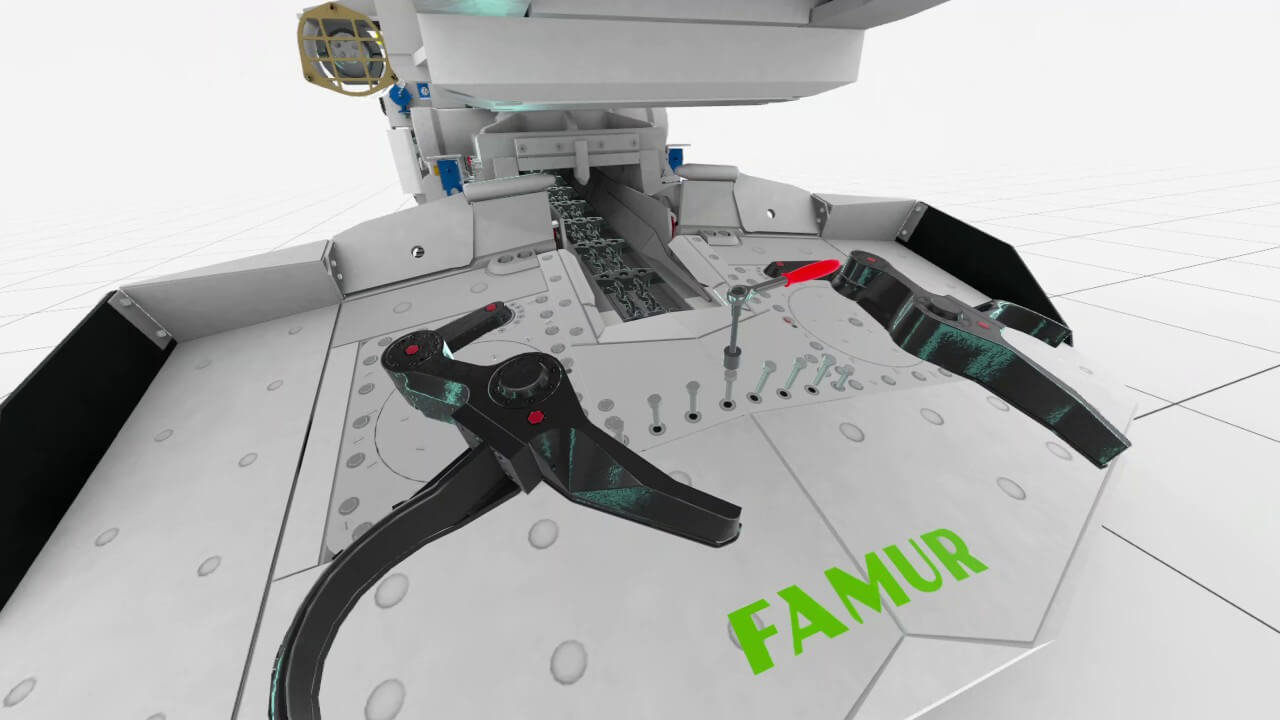

- Client: Famur S.A.

- Range of work: VR training platform, Applications for VR headsets and PC, 3D modeling of industrial equipment, Technical simulations, Interactive training scenarios, Admin panel integration

- Technologies:

- Duration of project: 3 years

- Number of devs: 5

Description:

A modern VR training platform for the heavy industry

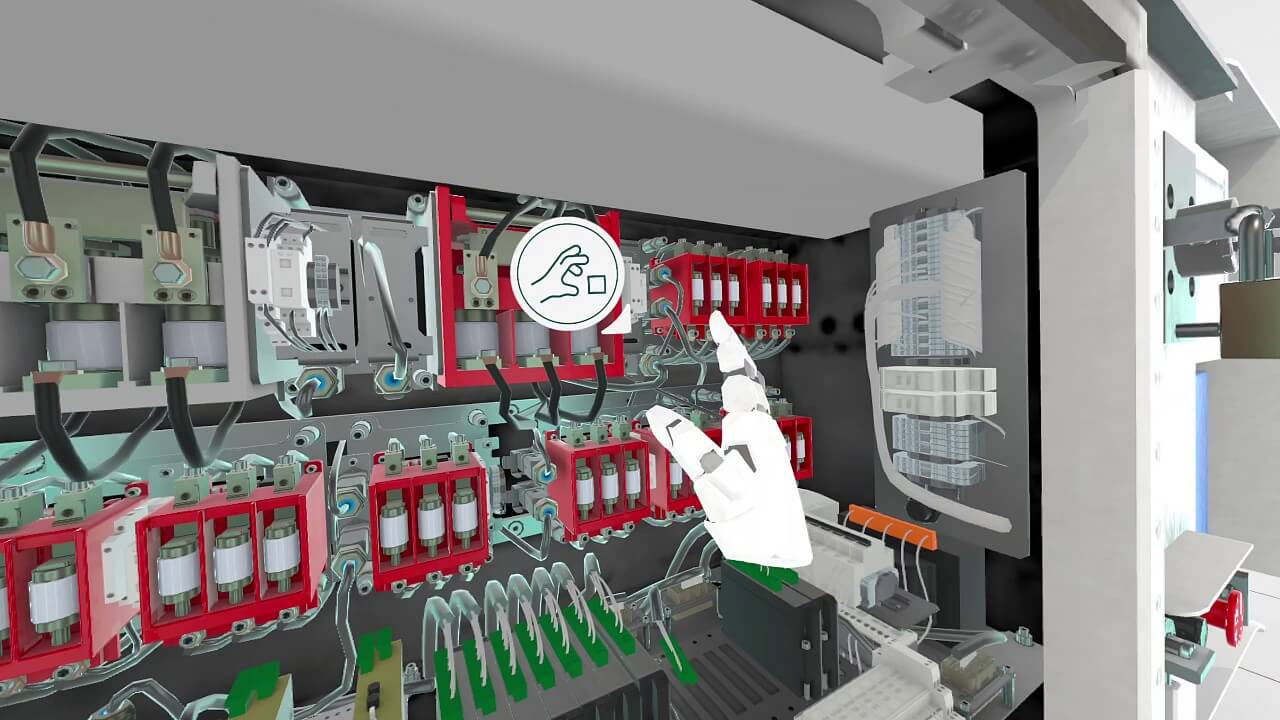

For FAMUR – a leading manufacturer of mining machinery – we implemented BellVR, an advanced training platform based on virtual reality (VR). This immersive solution enables safe, realistic and fully interactive technical training in a 3D environment. It allows service technicians and operators to practice procedures without the risk associated with real-world training.

Customized scenarios and realistic animations

The implementation includes over 120 training scenarios, created based on technical documentation and close collaboration with experts. Participants can either follow step-by-step tutorials or actively perform procedures with the help of voice guidance and interactive prompts. The scenarios feature realistic animations and detailed 3D models of industrial machinery, including gearboxes and shield supports.

Industrial simulations and VR presentations

BellVR is used not only for technical education but also for showcasing equipment during industry trade fairs in Poland and abroad – including Katowice and Las Vegas. The ability to host multiple users in the same virtual space allows for dynamic industrial simulations, such as visualizing gearbox operation or the movement of longwall shields.

Remote access and cross-platform compatibility

The BellVR platform is fully scalable. In addition to VR headsets (e.g., Meta Quest), training materials are also available via web and mobile apps. The system supports remote training sessions and allows real-time collaboration regardless of the user’s location.

Learn more about the training room and use of VR headsets in FAMUR’s official post and in our case study.